OUR CAPABILITIES

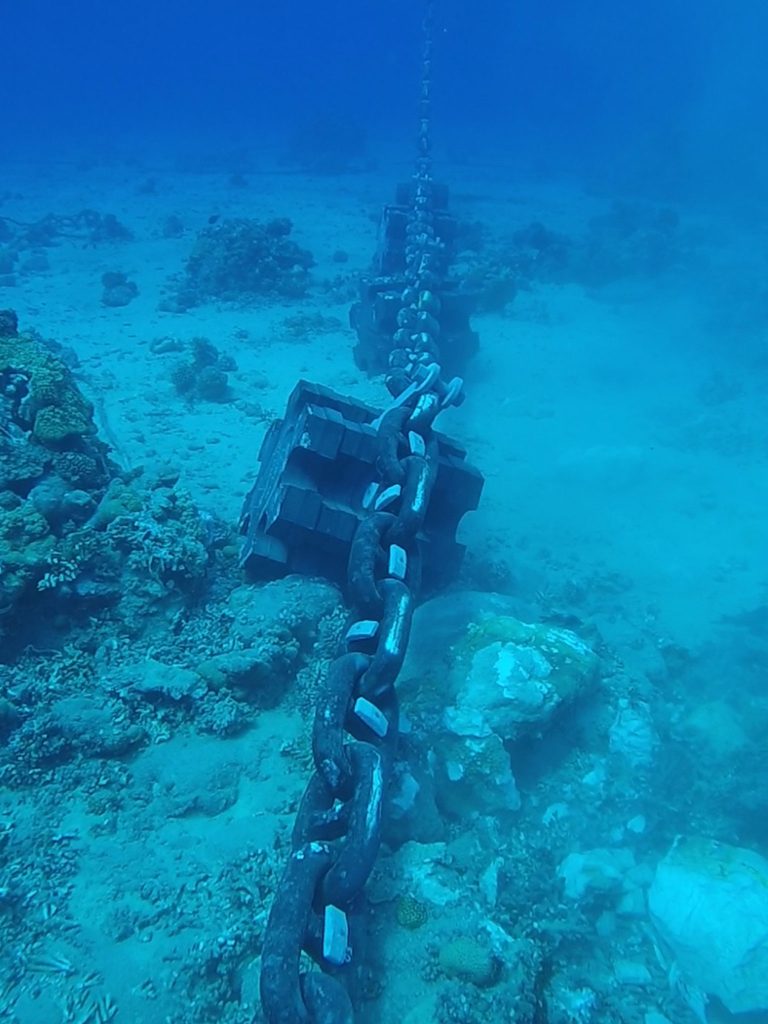

Marine Fabrication

Marine fabrication is the process of constructing complex and heavy-duty structures or components capable of withstanding extended lengths of time under the pressure of large bodies of water. Marine fabrication requires heavy duty materials like stainless steel and aluminum due to their high corrosion resistance, allowing them to withstand the high pressure and harsh conditions of saltwater bodies. Whether the project is buoyant or subaquatic, we provide quality metal services capable of resisting the corrosive effects of saltwater, extreme temperatures, and intense pressure. Our expertise ensures that each structure is built for longevity, durability, and reliability, offering performance in even the most challenging marine environments.

Heavy Fabrication

Marine Grade

Load Testing

Heavy Plate

Large Assembly

Hardware

Waterjet

Laser

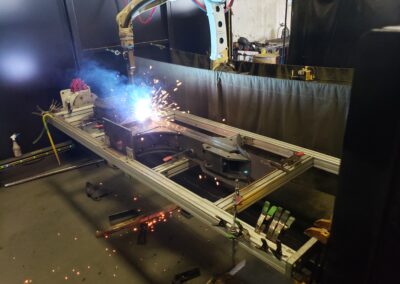

Heavy fabrication refers to the process of constructing large, complex, and heavy-duty structures or components using advanced techniques like cutting, welding, bending, and assembly. It typically involves working with materials like steel and other metals to produce products that can withstand high pressure, heavy loads, and harsh conditions, often for industries like construction, manufacturing, and transportation. Hiring a CNC machine and fabrication service ensures precision, efficiency, and customization in producing these components. With CNC technology, even the most intricate designs can be manufactured with consistent accuracy, ensuring the highest quality while reducing material waste and production time, making it a smart investment for any heavy fabrication needs.

General Welding

Partnering with CNC Machine and Fabrication for welding on large-scale projects offers several key advantages. Our expertise in precision welding ensures strong, durable joints capable of withstanding extreme conditions, making them ideal for industries like construction, oil and gas, and marine environments. We can handle complex welding tasks with high accuracy, ensuring that even large-scale projects are completed with consistent quality. Additionally, our experience in managing large volumes of work means that projects are completed on time and within budget, reducing downtime and ensuring smooth operations. When you need reliable, high-quality welding for a large-scale project, CNC machine and Fabrication is the trusted choice.

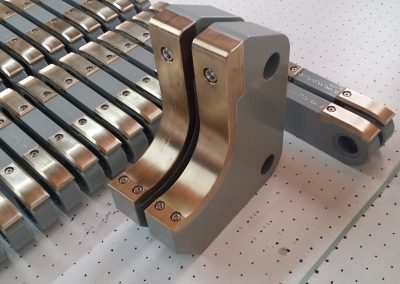

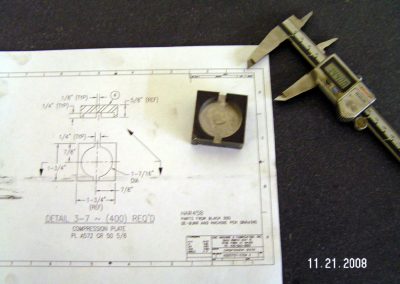

Plate and Sheet Fabrication

An important choice in industrial manufacturing is the type of metal that will give a project the best form, function, engineering stress analysis as well as durability. Whether our customers are looking for heavy plate or thin sheet metal, our processes are designed to handle a wide range of needs from thick plate to sheet metal bending and forming. We specialize in exotic material needs for a wide variety of sectors, including marine builds.

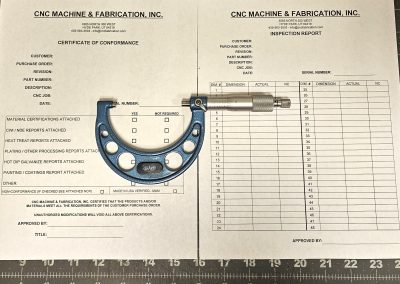

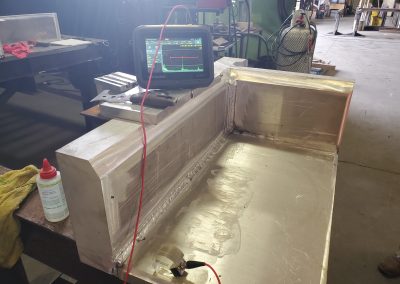

Assembly and Testing

At CNC Machine and Fabrication we want you to feel safe in knowing that your product is assembled with care and well tested, so that it lives up to the service the product is trying to provide. From top to bottom, CNC provides the assembly of machined and fabricated parts, so that your product can arrive finished and ready to go. Furthermore, we can provide testing, so you can verify that all work done is of the highest quality, meets your specifications, and performs flawlessly under real-world conditions. Our comprehensive approach guarantees that your product is not only reliable but also ready for the demands of its intended use.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.